DeepMould: The Ultimate Metal Fabricators & Leading Plastic Injection Molding Supplier for Your Business Success

In today's highly competitive manufacturing landscape, companies are constantly seeking reliable partners who can provide high-quality metal fabrication and precision plastic injection molding solutions. Among the industry leaders, DeepMould has established a stellar reputation as a premier metal fabricator and a trusted plastic injection molding supplier. With a focus on innovation, quality, and customer satisfaction, DeepMould has positioned itself as an indispensable player in the manufacturing sector.

An Unmatched Commitment to Quality Manufacturing

One of the core reasons why DeepMould stands out in the competitive world of metal fabrication and plastic molding is its unwavering commitment to excellence. The company employs advanced manufacturing technologies, precision engineering, and rigorous quality control processes to ensure every product meets the highest standards.

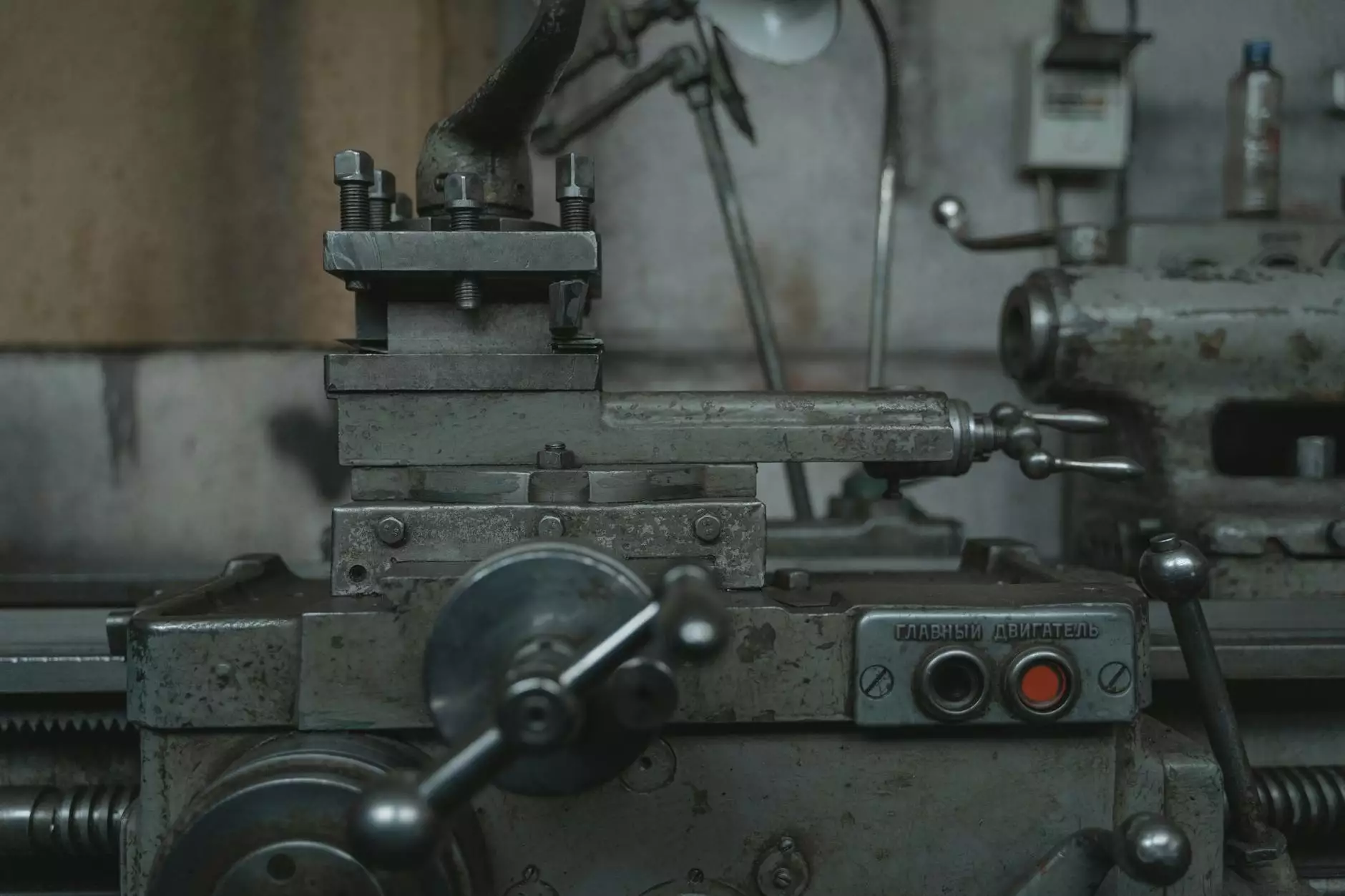

Quality assurance begins at the design stage, where experts collaborate with clients to optimize product functionality and manufacturability. In the production process, state-of-the-art machinery, such as CNC machines, laser cutters, and injection molding presses, are utilized to deliver flawless results. Furthermore, comprehensive testing and inspection procedures guarantee that each batch complies with industry standards and client specifications.

Why DeepMould Is the Preferred Metal Fabricator

DeepMould's expertise as a metal fabricator derives from decades of experience and a highly skilled team dedicated to innovative solutions. Here are some key aspects that make DeepMould your ideal partner:

- Comprehensive Fabrication Capabilities: From sheet metal forming and welding to machining and surface finishing, DeepMould offers an extensive range of metal fabrication services tailored to diverse industry needs including automotive, aerospace, medical devices, and industrial machinery.

- Use of Premium Materials: The company works with high-grade materials such as stainless steel, aluminum, brass, copper, and specialized alloys to ensure durability, corrosion resistance, and performance even under challenging conditions.

- Advanced Manufacturing Technology: Equipped with the latest technology, DeepMould guarantees precision, efficiency, and scalability for both small-batch and large-volume production runs.

- Custom Metal Components: The company's engineering team excels in developing custom solutions that optimize design, reduce material waste, and improve overall product performance.

DeepMould as a Plastic Injection Molding Supplier: Delivering Precision and Innovation

When it comes to plastic injection molding, DeepMould has built a reputation for delivering intricate, high-quality plastic parts that meet stringent specifications. As a reputed plastic injection molding supplier, DeepMould combines cutting-edge technology with extensive industry expertise to create innovative, cost-effective solutions.

State-of-the-Art Injection Molding Equipment

DeepMould's manufacturing facility is outfitted with a wide range of high-precision injection molding machines, including hydraulic, electric, and hybrid presses. This equipment supports mold sizes from tiny micro-components to large structural parts, offering flexibility and capability unmatched in the industry.

Customized Solutions for Diverse Industry Needs

Whether it’s consumer electronics, medical devices, automotive interior components, or packaging, DeepMould develops tailored plastic molding solutions that align with client specifications. They focus on delivering parts with tight tolerances, smooth surface finishes, and complex geometries that are difficult to produce with lesser quality suppliers.

Design for Manufacturability (DFM) and Rapid Prototyping

DeepMould’s engineers utilize advanced CAD/CAM software to optimize plastic part designs, minimizing material waste, reducing cycle times, and ensuring ease of assembly. The company also offers rapid prototyping services to allow clients to validate designs quickly before mass production, significantly shortening product development cycles.

The DeepMould Advantage: Integration of Metal and Plastic Manufacturing

One of the most significant advantages of choosing DeepMould is their integrated approach, combining expertise in both metal fabrication and plastic molding. This synergy enables the company to serve as a comprehensive manufacturing partner, capable of delivering multi-material components and assemblies that meet the most demanding requirements.

Benefits of this integrated approach include:

- Streamlined Supply Chain: Single-source provider reduces lead times and communication complexity.

- Enhanced Design Flexibility: Ability to develop fully integrated parts combining metal and plastic for optimized performance and cost-efficiency.

- Improved Quality Control: Centralized quality assurance ensures consistency across all components.

- Cost Savings: Reduced logistics and inventory costs by consolidating manufacturing processes.

DeepMould’s Dedication to Sustainability and Eco-Friendly Manufacturing

As the manufacturing industry evolves, sustainability has become more than just a buzzword; it’s a necessity. DeepMould recognizes its responsibility to minimize environmental impact by employing eco-friendly practices, such as recycling scrap materials, optimizing energy use, and adopting environmentally safe chemicals and lubricants.

The company also explores innovative solutions like biodegradable plastics and energy-efficient machinery to support clients’ sustainability goals without compromising quality or performance.

Customer-Centric Approach and Global Reach

DeepMould’s success stems from its unwavering focus on customer satisfaction. The company maintains transparent communication channels, offers technical support throughout the project lifecycle, and guarantees on-time delivery. Their dedicated customer service team ensures clients receive tailored solutions aligned with their specific needs.

Moreover, DeepMould serves a global client base, leveraging international logistics networks to deliver products across North America, Europe, Asia, and beyond. This global reach ensures rapid response times, reliable supply chains, and flexible scalability for international businesses.

Innovative Technologies Shaping the Future of Manufacturing

DeepMould stays ahead of industry trends by continuously investing in emerging technologies such as:

- Additive Manufacturing (3D Printing): For rapid prototyping and complex part production

- Smart Manufacturing with IoT: Real-time monitoring and predictive maintenance

- Automation and Robotics: Enhanced precision, reduced labor costs, and increased throughput

- Advanced Materials: High-performance plastics, composites, and lightweight alloys

This forward-thinking approach ensures that clients benefit from cutting-edge solutions that enhance product quality and reduce time-to-market.

Partner with DeepMould for Long-Term Success

Choosing the right manufacturing partner is crucial to the success of any product development journey. DeepMould offers more than just fabrication; they become an extension of your team, providing strategic guidance, innovative solutions, and unwavering support.

Whether you need a dependable plastic injection molding supplier or comprehensive metal fabrication services, DeepMould is committed to helping you achieve your business objectives with precision, quality, and efficiency. Collaborate with a company that values your success as much as you do.

Contact DeepMould Today to Elevate Your Manufacturing Capabilities

To experience the difference that a leading metal fabricator and plastic injection molding supplier can make for your enterprise, reach out to DeepMould. Discover how they blend technological innovation, unmatched quality, and dedicated service to turn your ideas into reality, ensuring your products stand out in the market.

DeepMould – Your Trusted Partner in Manufacturing Excellence.